LooseNut

Active Member

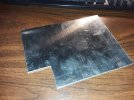

Spent a little time and made up the plate tonight based on the picture that was shown in the Canada RC forum.

The Aluminum plate is .125" (1/8" or 3.1mm) 6061-T6, I have the plate on hand for doing stuff like this, but I'm sure you could use the Aluminum strap of the same thickness available at a local homebuilding outlet or Hardware store. The key here is the mass that will dampen and shift the resonance the Rx is seeing.

An easy layout is shown in the second picture. I cut it out with a hacksaw, squared it up with a hand file and used a needle file to make the cutouts for the Rx bottom screws. They are just in case you need to open it up at a later date. As with the OP on the CRC forum, I intend to epoxy it on, so the choice is yours on the notches.

Once the notches were in I weighed it to see where I was with weight and then started the tinkery task of filing down the extra weight. Since I had filed the width to the same as the Rx, I gradually took metal off the long end (ref from the notches) until I got the weight where I wanted. 7.70 grams on the nose.

Now to rough up the glue area, clean the Rx bottom and scuff it so I can apply a thin layer of 20 minute Epoxy.

I like to apply a very thin coat to both surfaces. That method ensures adhesive is on both surfaces when you put it together. Thin being key so you don't have a bunch of squeeze out.

Ta Daaaa!

Ok, now to take things apart so I can put them back together. The Torture of development. Hahaha!

The Aluminum plate is .125" (1/8" or 3.1mm) 6061-T6, I have the plate on hand for doing stuff like this, but I'm sure you could use the Aluminum strap of the same thickness available at a local homebuilding outlet or Hardware store. The key here is the mass that will dampen and shift the resonance the Rx is seeing.

An easy layout is shown in the second picture. I cut it out with a hacksaw, squared it up with a hand file and used a needle file to make the cutouts for the Rx bottom screws. They are just in case you need to open it up at a later date. As with the OP on the CRC forum, I intend to epoxy it on, so the choice is yours on the notches.

Once the notches were in I weighed it to see where I was with weight and then started the tinkery task of filing down the extra weight. Since I had filed the width to the same as the Rx, I gradually took metal off the long end (ref from the notches) until I got the weight where I wanted. 7.70 grams on the nose.

Now to rough up the glue area, clean the Rx bottom and scuff it so I can apply a thin layer of 20 minute Epoxy.

I like to apply a very thin coat to both surfaces. That method ensures adhesive is on both surfaces when you put it together. Thin being key so you don't have a bunch of squeeze out.

Ta Daaaa!

Ok, now to take things apart so I can put them back together. The Torture of development. Hahaha!